Unveiling the Essence of Makeup Water Pipes: A Comprehensive Exploration

Related Articles: Unveiling the Essence of Makeup Water Pipes: A Comprehensive Exploration

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Unveiling the Essence of Makeup Water Pipes: A Comprehensive Exploration. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Unveiling the Essence of Makeup Water Pipes: A Comprehensive Exploration

The term "makeup water pipe" may sound unfamiliar to many, but it represents a crucial component within the intricate network of plumbing systems. This article delves into the intricacies of makeup water pipes, elucidating their role, functionality, and significance in ensuring the efficient and safe operation of various water-dependent systems.

Understanding the Role of Makeup Water Pipes:

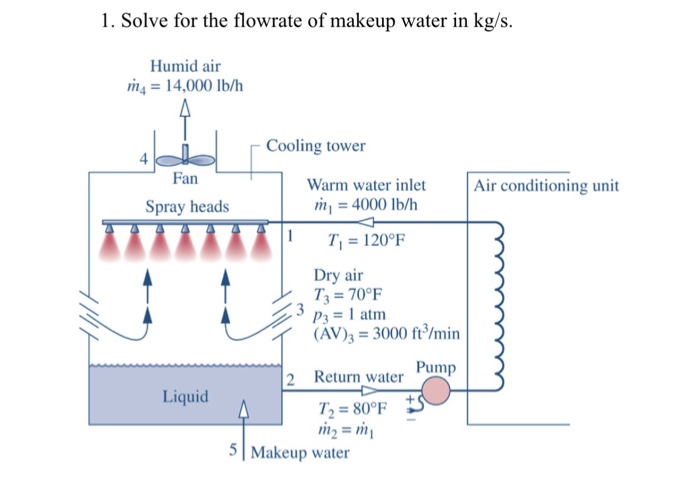

Makeup water pipes are integral to maintaining the proper water levels and pressure within closed-loop systems, such as those found in boilers, cooling towers, and hydronic heating systems. These systems rely on a consistent water volume to function effectively. However, due to factors like evaporation, leaks, and water usage, the water level within these systems can decrease over time. This is where makeup water pipes come into play.

The Function of Makeup Water Pipes:

Makeup water pipes act as the replenishment mechanism for closed-loop systems. They provide a continuous supply of fresh water to compensate for any losses, ensuring that the system maintains its optimal operating pressure and water level. This continuous replenishment is essential for the following reasons:

- Maintaining System Pressure: A decline in water level within a closed-loop system can lead to a drop in pressure, impacting the system’s efficiency and potentially causing damage. Makeup water pipes prevent this by replenishing the lost water, maintaining the necessary pressure for proper operation.

- Preventing Cavitation: Cavitation occurs when water boils within a system due to low pressure. This phenomenon can damage pumps and other system components. Makeup water pipes ensure sufficient water levels, preventing cavitation and safeguarding the integrity of the system.

- Ensuring Optimal Performance: By maintaining the correct water level and pressure, makeup water pipes contribute to the efficient and reliable operation of the entire system. This translates to improved energy efficiency, reduced maintenance costs, and prolonged system lifespan.

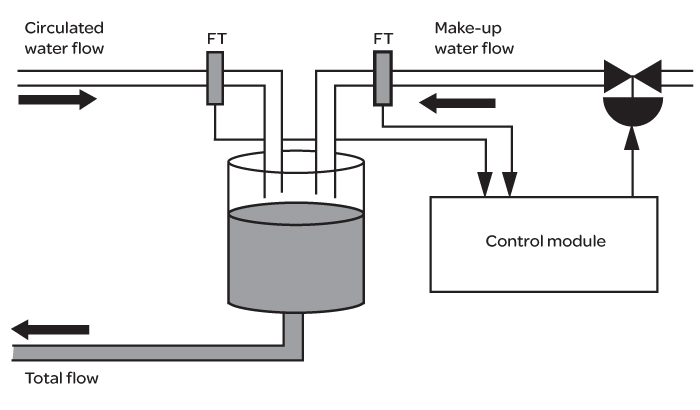

The Components of a Makeup Water Pipe System:

A typical makeup water pipe system comprises several key components:

- Makeup Water Tank: This tank stores the fresh water that will be supplied to the closed-loop system.

- Makeup Water Pump: This pump transfers water from the makeup water tank to the closed-loop system.

- Control Valve: This valve regulates the flow of water from the makeup water tank to the closed-loop system, ensuring that the system receives only the necessary amount of water.

- Pressure Relief Valve: This valve releases excess pressure within the closed-loop system, preventing over-pressurization and potential damage.

- Water Treatment Equipment: Depending on the application, the makeup water pipe system may include water treatment equipment to remove impurities and ensure the quality of the water entering the closed-loop system.

Types of Makeup Water Pipes:

Makeup water pipes can be categorized based on the type of system they serve:

- Boiler Makeup Water Pipes: These pipes supply water to boilers, ensuring that the boiler water level remains consistent and preventing the formation of steam bubbles that could lead to boiler failure.

- Cooling Tower Makeup Water Pipes: Cooling towers rely on a constant water supply to maintain their cooling efficiency. Makeup water pipes replenish the water lost through evaporation, ensuring optimal performance.

- Hydronic Heating System Makeup Water Pipes: These pipes provide water to hydronic heating systems, maintaining the water level and pressure required for efficient heat distribution throughout the system.

The Importance of Proper Makeup Water Pipe Installation:

Correct installation of makeup water pipes is crucial for their proper functioning and the safety of the entire system. Improper installation can lead to several issues, including:

- Leaks: A poorly installed makeup water pipe can leak, leading to water damage and wasting water resources.

- Pressure Imbalances: Incorrect pipe sizing or valve placement can disrupt the pressure balance within the system, affecting its performance and potentially causing damage.

- Contamination: If the makeup water pipe system is not properly sealed, contaminants from the water supply can enter the closed-loop system, impacting its efficiency and potentially causing corrosion.

Benefits of Utilizing Makeup Water Pipes:

The use of makeup water pipes offers numerous benefits, including:

- Increased System Efficiency: By maintaining optimal water levels and pressure, makeup water pipes enhance the overall efficiency of the closed-loop system, leading to reduced energy consumption and operating costs.

- Extended System Lifespan: By preventing cavitation and other detrimental conditions, makeup water pipes contribute to the longevity of the closed-loop system, reducing the need for premature replacements.

- Enhanced Safety: Makeup water pipes ensure the safe operation of the closed-loop system by preventing pressure imbalances and potential damage.

- Reduced Maintenance Costs: By minimizing the risk of system failures, makeup water pipes contribute to lower maintenance costs over the system’s lifetime.

FAQs Regarding Makeup Water Pipes:

Q: What are the signs of a failing makeup water pipe system?

A: Signs of a failing makeup water pipe system include:

- Decreased water pressure: A drop in water pressure within the closed-loop system can indicate a leak or a malfunctioning makeup water pump.

- Visible leaks: Leaking pipes or fittings are obvious signs of a failing makeup water pipe system.

- Excessive noise: Unusual noises from the system, such as gurgling or rattling, may indicate a problem with the makeup water pipe system.

- System malfunction: If the closed-loop system is not functioning properly, such as a boiler failing to heat or a cooling tower not cooling effectively, a failing makeup water pipe system could be the culprit.

Q: How often should makeup water pipes be inspected?

A: It is recommended to inspect makeup water pipes at least annually to ensure their proper functioning and identify any potential issues. Regular inspections can prevent costly repairs and ensure the safe and efficient operation of the system.

Q: What is the best way to maintain makeup water pipes?

A: Maintaining makeup water pipes involves several key steps:

- Regular inspection: Inspect the pipes, fittings, and valves for leaks, corrosion, or other signs of damage.

- Water quality monitoring: Monitor the quality of the makeup water to ensure it meets the requirements of the closed-loop system.

- Pump maintenance: Regularly inspect and maintain the makeup water pump to ensure its proper operation.

- Valve maintenance: Inspect and lubricate the valves to ensure they operate smoothly and prevent leaks.

- Treatment system maintenance: If the makeup water pipe system includes water treatment equipment, ensure its proper operation and maintenance.

Tips for Optimizing Makeup Water Pipe Systems:

- Choose the right size pipe: Ensure the pipe size is adequate for the flow rate required by the closed-loop system.

- Use high-quality materials: Select durable and corrosion-resistant materials for the pipes and fittings.

- Properly install the system: Ensure that the makeup water pipe system is installed correctly and securely to prevent leaks and other issues.

- Regularly monitor the system: Keep an eye on the water level and pressure within the closed-loop system to identify any potential problems early on.

- Maintain the system proactively: Regularly inspect and maintain the makeup water pipe system to ensure its long-term performance and reliability.

Conclusion:

Makeup water pipes are essential components of closed-loop systems, ensuring their efficient and safe operation. By replenishing lost water and maintaining the correct pressure, makeup water pipes play a crucial role in preventing system failures, extending system lifespan, and reducing maintenance costs. Recognizing the importance of these pipes and implementing proper installation, inspection, and maintenance practices can contribute significantly to the longevity and reliable performance of various water-dependent systems.

Closure

Thus, we hope this article has provided valuable insights into Unveiling the Essence of Makeup Water Pipes: A Comprehensive Exploration. We appreciate your attention to our article. See you in our next article!