Understanding the Essential Role of Makeup Water Tanks in Modern Infrastructure

Related Articles: Understanding the Essential Role of Makeup Water Tanks in Modern Infrastructure

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Understanding the Essential Role of Makeup Water Tanks in Modern Infrastructure. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Understanding the Essential Role of Makeup Water Tanks in Modern Infrastructure

- 2 Introduction

- 3 Understanding the Essential Role of Makeup Water Tanks in Modern Infrastructure

- 3.1 Defining Makeup Water Tanks: A Vital Component of Water Treatment

- 3.2 The Importance of Makeup Water Tanks: Ensuring Uninterrupted Water Supply

- 3.3 The Working Mechanism of Makeup Water Tanks: A Detailed Explanation

- 3.4 Factors Influencing the Design and Selection of Makeup Water Tanks

- 3.5 Types of Makeup Water Tanks: A Comprehensive Overview

- 3.6 Advantages of Using Makeup Water Tanks: Enhancing Water Management Efficiency

- 3.7 FAQs About Makeup Water Tanks: Addressing Common Queries

- 3.8 Tips for Maintaining Makeup Water Tanks: Ensuring Optimal Performance

- 3.9 Conclusion: The Importance of Makeup Water Tanks in Modern Water Management

- 4 Closure

Understanding the Essential Role of Makeup Water Tanks in Modern Infrastructure

Water is a fundamental resource, essential for life and a cornerstone of modern society. Its efficient management and distribution are paramount, and within this intricate system, makeup water tanks play a crucial role. This article delves into the intricacies of makeup water tanks, examining their purpose, function, and significance in maintaining reliable water supply systems.

Defining Makeup Water Tanks: A Vital Component of Water Treatment

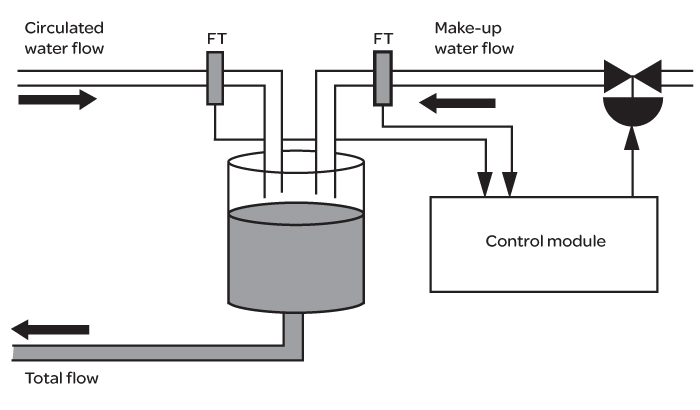

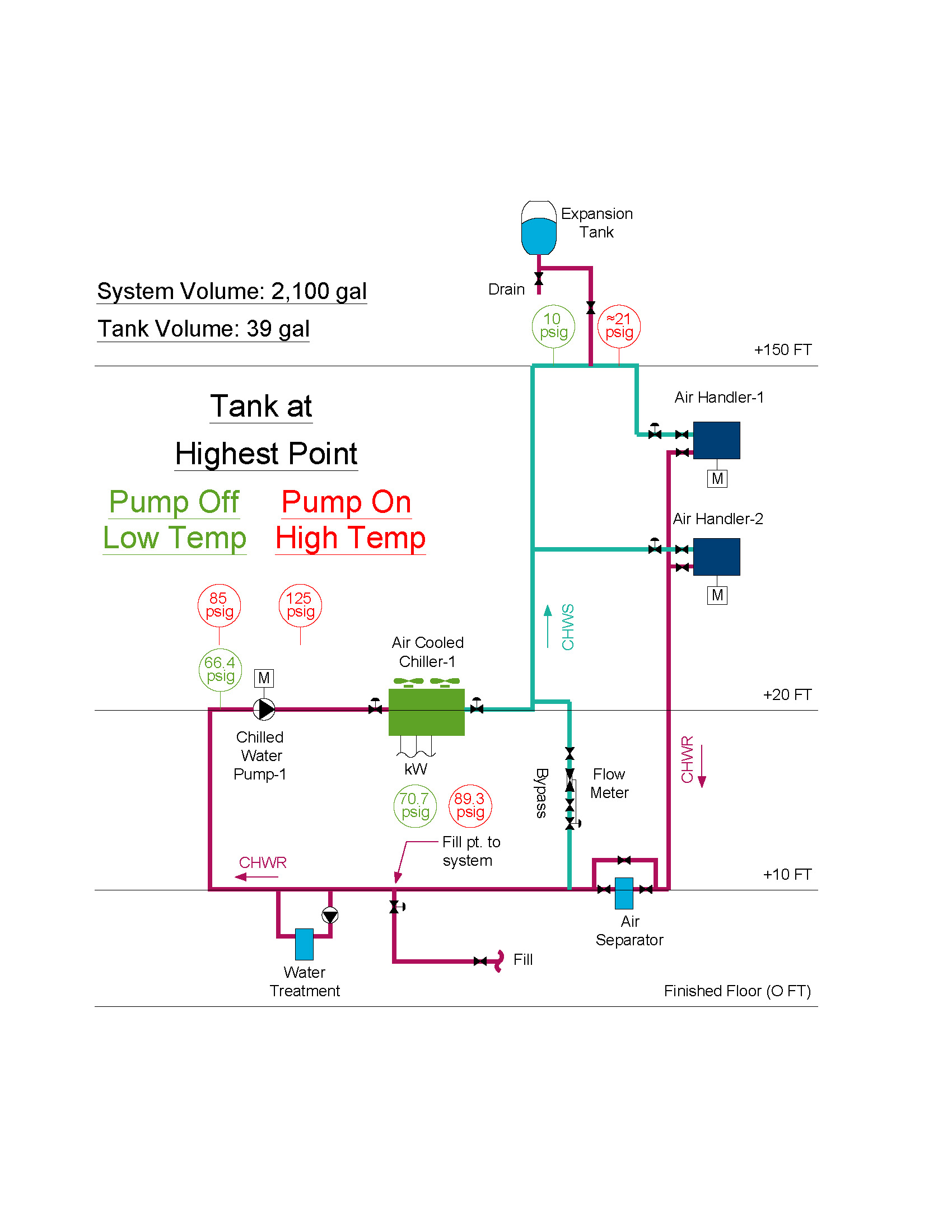

Makeup water tanks, often referred to as "makeup tanks," are integral components of water treatment facilities, particularly in closed-loop systems. Their primary function is to replenish water lost during the treatment process, ensuring a consistent flow and maintaining pressure within the system. These tanks act as reservoirs, storing treated water that is then introduced back into the loop to compensate for any losses incurred through evaporation, leakage, or consumption.

The Importance of Makeup Water Tanks: Ensuring Uninterrupted Water Supply

The importance of makeup water tanks cannot be overstated. Their presence guarantees a continuous and reliable water supply, crucial for various applications including:

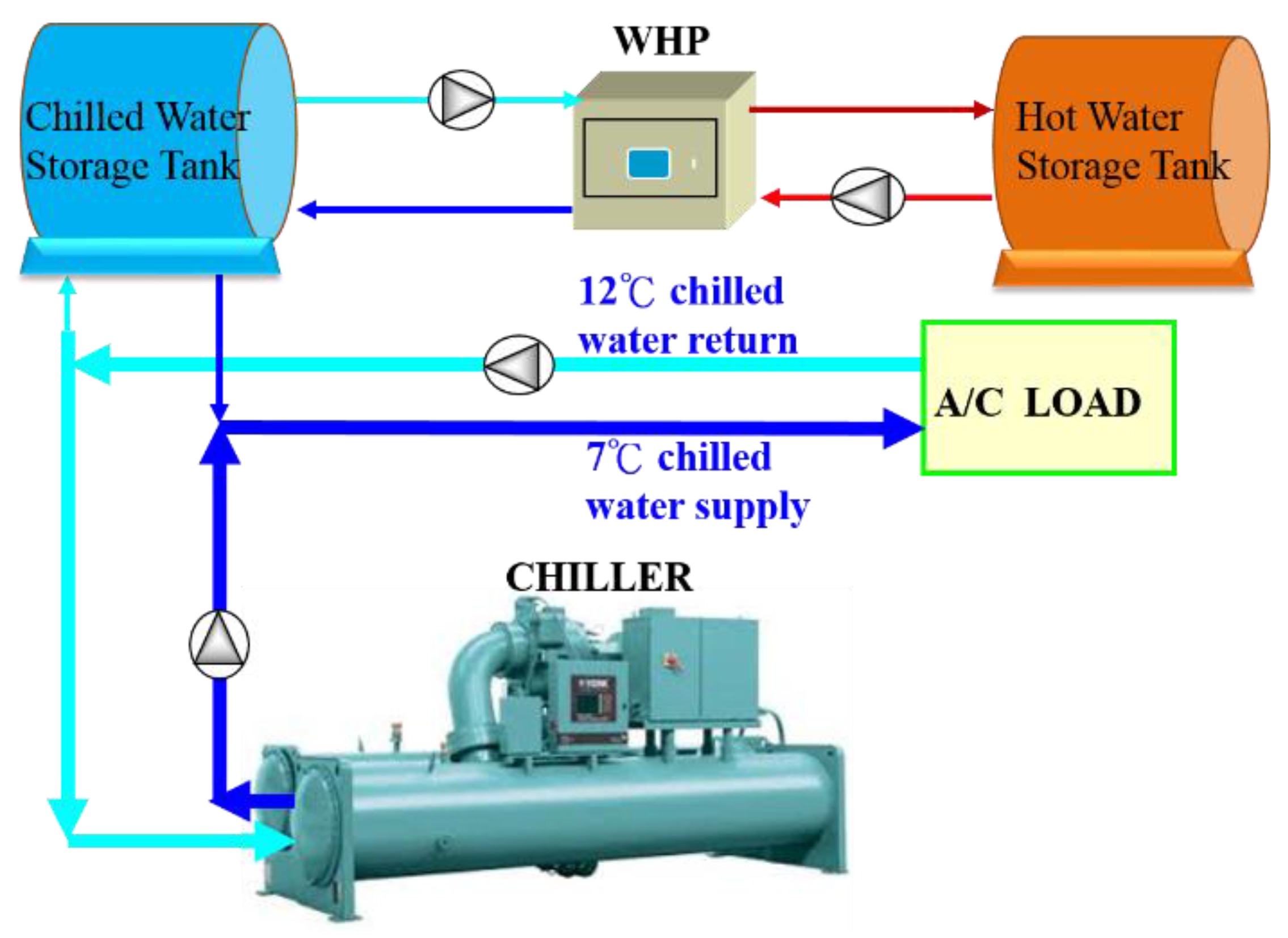

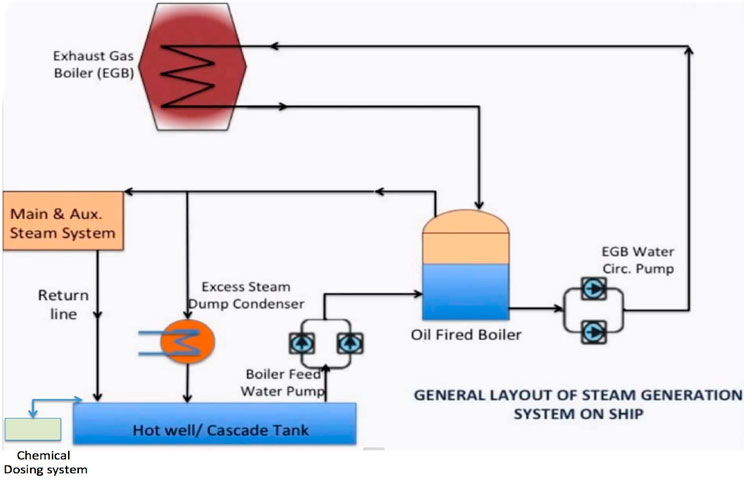

- Industrial Processes: In industrial settings, consistent water flow is vital for manufacturing processes, cooling systems, and other operations. Makeup tanks ensure a constant supply, preventing disruptions and production delays.

- Commercial Buildings: From office towers to hotels, commercial buildings rely on efficient water systems for sanitation, cooling, and fire suppression. Makeup tanks safeguard against water shortages, ensuring uninterrupted service and building safety.

- Residential Communities: In residential areas, makeup water tanks play a vital role in maintaining adequate water pressure for household needs, including drinking, bathing, and appliance usage. They prevent fluctuations in water pressure and ensure a smooth water supply.

The Working Mechanism of Makeup Water Tanks: A Detailed Explanation

The operation of a makeup water tank is straightforward yet essential. It involves a series of interconnected processes:

- Water Treatment: Raw water undergoes a series of treatment processes, including filtration, disinfection, and chemical adjustments, to remove impurities and contaminants.

- Water Storage: The treated water is then stored in the makeup water tank, serving as a reservoir for replenishing the system.

- Water Demand: As water is consumed or lost through various means, the system’s pressure drops.

- Water Replenishment: The makeup water tank automatically replenishes the system by releasing stored water, maintaining the desired pressure and flow rate.

- Continuous Cycle: This process repeats continuously, ensuring a constant supply of clean and treated water for various purposes.

Factors Influencing the Design and Selection of Makeup Water Tanks

The design and selection of a makeup water tank are influenced by several key factors, including:

- Water Demand: The volume of water required by the system dictates the size and capacity of the makeup tank. Higher water demand necessitates larger tanks to ensure adequate replenishment.

- Water Quality: The specific requirements for water quality, such as pH levels, chemical composition, and purity, influence the material used for the tank and its associated filtration systems.

- Operating Pressure: The pressure at which the system operates determines the tank’s design and construction, ensuring its ability to withstand the pressure and deliver the required flow.

- Environmental Conditions: Factors such as temperature, humidity, and exposure to sunlight influence the tank’s material, insulation, and protective coatings.

Types of Makeup Water Tanks: A Comprehensive Overview

Makeup water tanks are available in various types, each suited to specific applications and requirements:

- Steel Tanks: Durable and cost-effective, steel tanks are commonly used in industrial and commercial settings. They are often coated with protective layers to prevent corrosion.

- Fiberglass Tanks: Lightweight and corrosion-resistant, fiberglass tanks are suitable for both indoor and outdoor installations. They are particularly well-suited for residential applications.

- Concrete Tanks: Durable and long-lasting, concrete tanks are often used for large-scale water storage. They are typically found in municipal water treatment facilities and industrial complexes.

- Plastic Tanks: Lightweight and flexible, plastic tanks are suitable for smaller applications, such as residential water storage. They are available in various sizes and configurations.

Advantages of Using Makeup Water Tanks: Enhancing Water Management Efficiency

The use of makeup water tanks offers numerous advantages, contributing to improved water management and system efficiency:

- Consistent Water Supply: Makeup tanks ensure a continuous and uninterrupted water supply, preventing disruptions to operations and ensuring a reliable flow.

- Pressure Regulation: They maintain consistent pressure within the system, preventing fluctuations and ensuring optimal performance of appliances and equipment.

- Water Conservation: By replenishing the system with treated water, makeup tanks minimize the need for drawing fresh water, reducing overall water consumption and promoting sustainability.

- Improved Water Quality: Makeup tanks provide a buffer against fluctuations in water quality, ensuring that the treated water delivered to the system remains consistent and meets established standards.

- Reduced Maintenance Costs: By maintaining a consistent water supply and pressure, makeup tanks minimize wear and tear on pumps and other equipment, reducing maintenance costs and extending their lifespan.

FAQs About Makeup Water Tanks: Addressing Common Queries

Q: What is the difference between a makeup water tank and a storage tank?

A: While both types of tanks store water, their primary functions differ. Makeup water tanks specifically replenish water lost within a closed-loop system, while storage tanks hold large volumes of water for distribution to various points within a network.

Q: How often should a makeup water tank be inspected and cleaned?

A: Regular inspections and cleaning are essential to maintain the integrity and functionality of the tank. The frequency of these tasks depends on the tank’s size, usage, and environmental conditions, but generally, annual inspections and cleaning are recommended.

Q: Can makeup water tanks be used for drinking water?

A: Makeup water tanks are not typically designed for storing drinking water. Their primary purpose is to replenish water within a closed-loop system. If drinking water is required, separate storage tanks specifically designed for potable water should be used.

Q: What are the safety considerations for makeup water tanks?

A: Safety considerations include ensuring proper ventilation to prevent the buildup of gases, regular inspections for leaks or corrosion, and ensuring the tank is securely anchored to prevent movement or damage.

Tips for Maintaining Makeup Water Tanks: Ensuring Optimal Performance

- Regular Inspections: Conduct regular inspections for leaks, corrosion, and other signs of damage, addressing any issues promptly to prevent further deterioration.

- Cleaning and Disinfection: Clean and disinfect the tank periodically to remove sediment and prevent the growth of bacteria or algae.

- Proper Ventilation: Ensure adequate ventilation to prevent the buildup of gases, particularly in enclosed spaces.

- Water Quality Monitoring: Monitor the water quality in the tank regularly to ensure it meets the system’s requirements.

- Professional Maintenance: Engage professional services for routine maintenance and inspections, ensuring proper operation and longevity of the tank.

Conclusion: The Importance of Makeup Water Tanks in Modern Water Management

Makeup water tanks are essential components of modern water management systems, playing a critical role in ensuring reliable and efficient water supply. Their ability to replenish water lost during treatment processes guarantees a continuous flow, maintaining pressure and ensuring the optimal operation of various applications. By understanding the importance, function, and maintenance of makeup water tanks, individuals and organizations can contribute to the efficient and sustainable management of this vital resource.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Essential Role of Makeup Water Tanks in Modern Infrastructure. We appreciate your attention to our article. See you in our next article!