Understanding Makeup Water Requirements in Cooling Towers: A Comprehensive Guide

Related Articles: Understanding Makeup Water Requirements in Cooling Towers: A Comprehensive Guide

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Understanding Makeup Water Requirements in Cooling Towers: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Understanding Makeup Water Requirements in Cooling Towers: A Comprehensive Guide

- 2 Introduction

- 3 Understanding Makeup Water Requirements in Cooling Towers: A Comprehensive Guide

- 3.1 What is Makeup Water?

- 3.2 Why is Makeup Water Essential?

- 3.3 Factors Influencing Makeup Water Requirements

- 3.4 Determining Makeup Water Requirements

- 3.5 Benefits of Optimized Makeup Water Management

- 3.6 FAQs Regarding Makeup Water Requirements

- 3.7 Tips for Effective Makeup Water Management

- 3.8 Conclusion

- 4 Closure

Understanding Makeup Water Requirements in Cooling Towers: A Comprehensive Guide

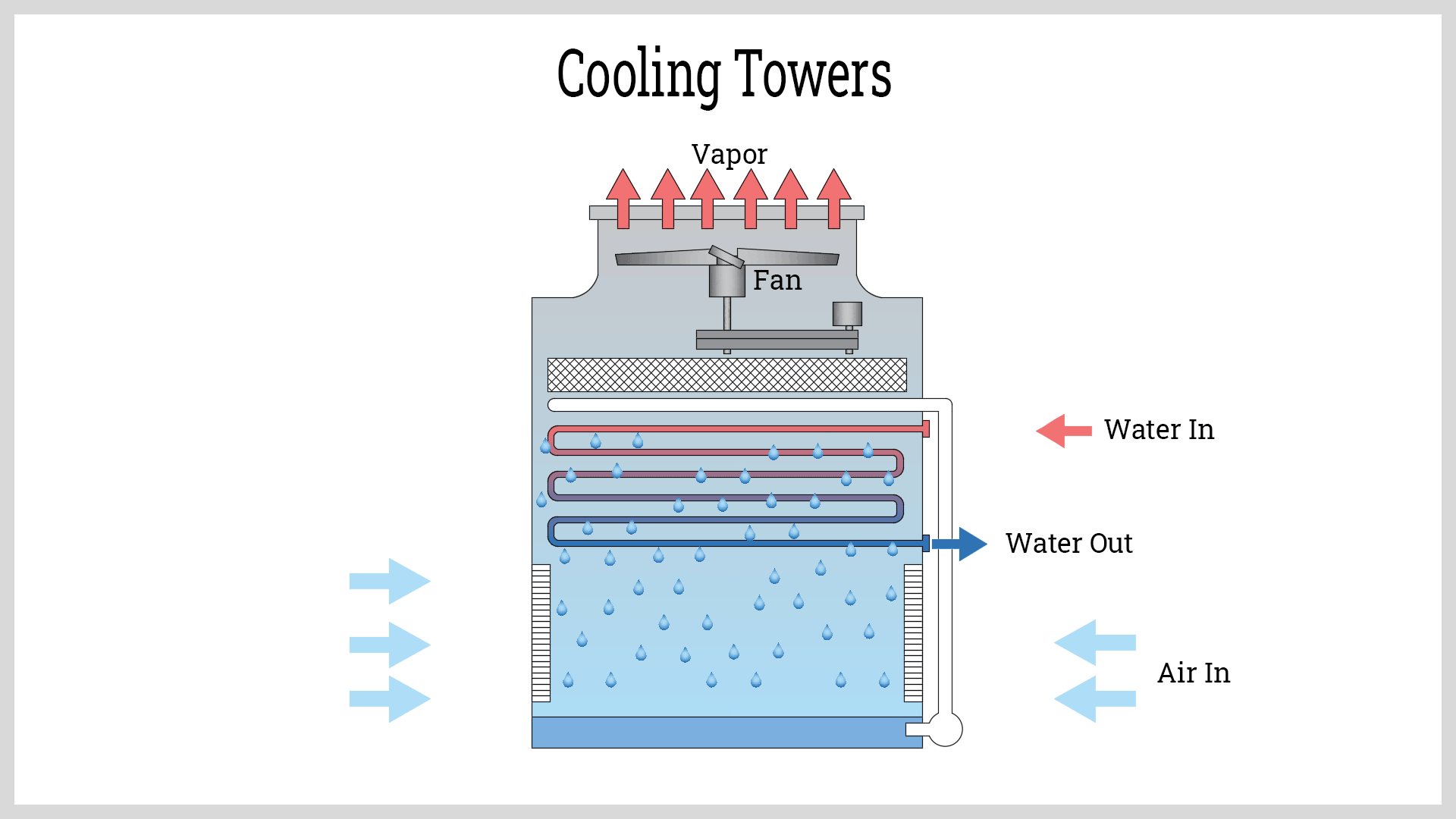

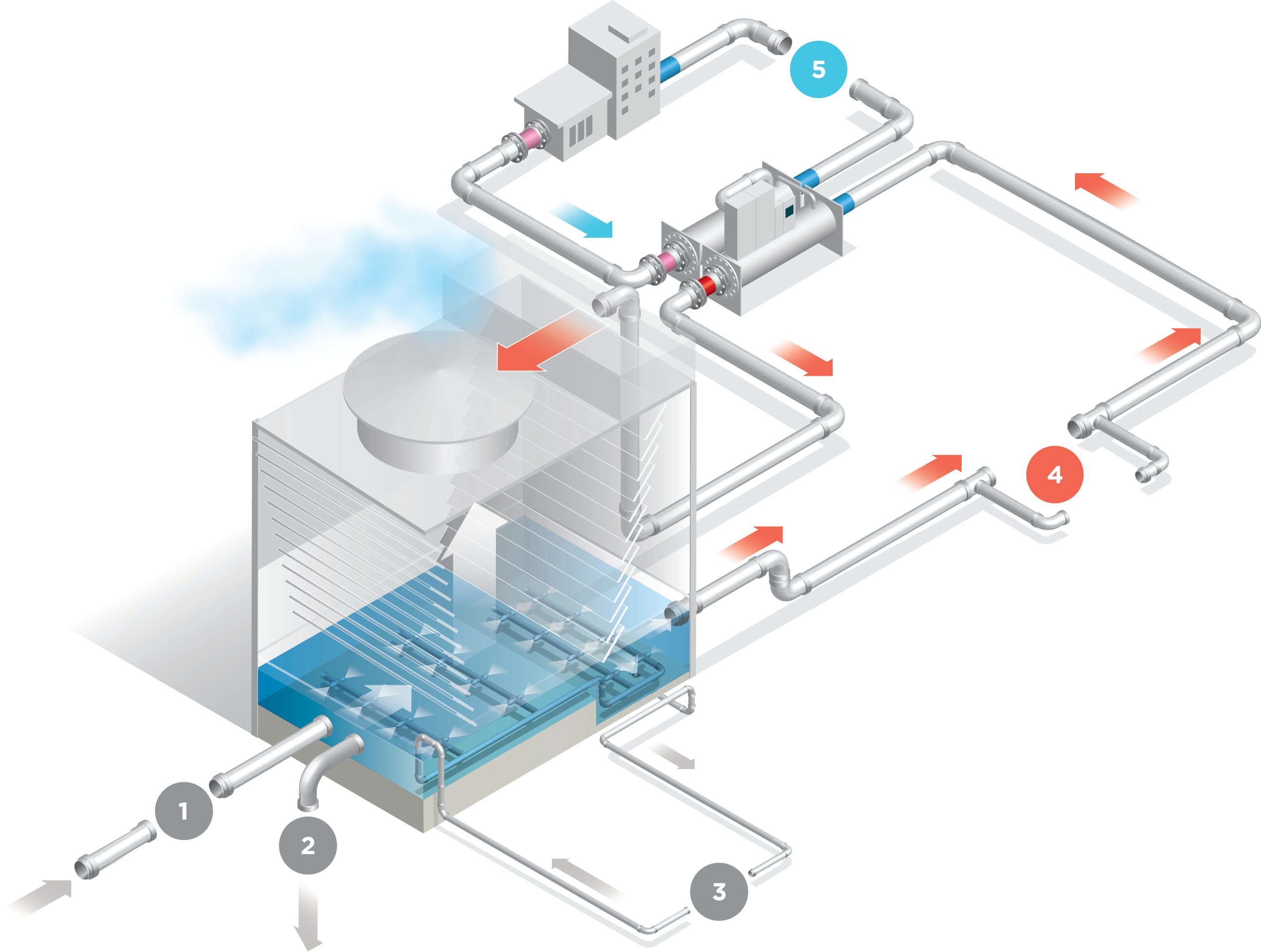

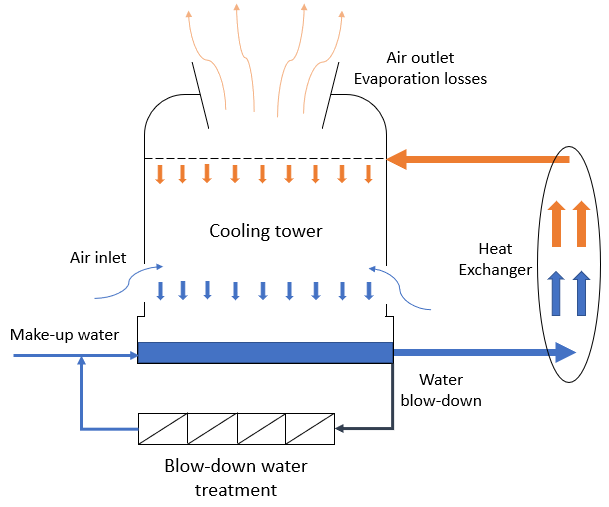

Cooling towers are essential components in many industrial and commercial processes, providing a critical function in heat rejection. These structures rely on a continuous cycle of water evaporation to dissipate heat, and maintaining the water level within the tower is crucial for its efficient operation. This is where the concept of "makeup water" comes into play.

What is Makeup Water?

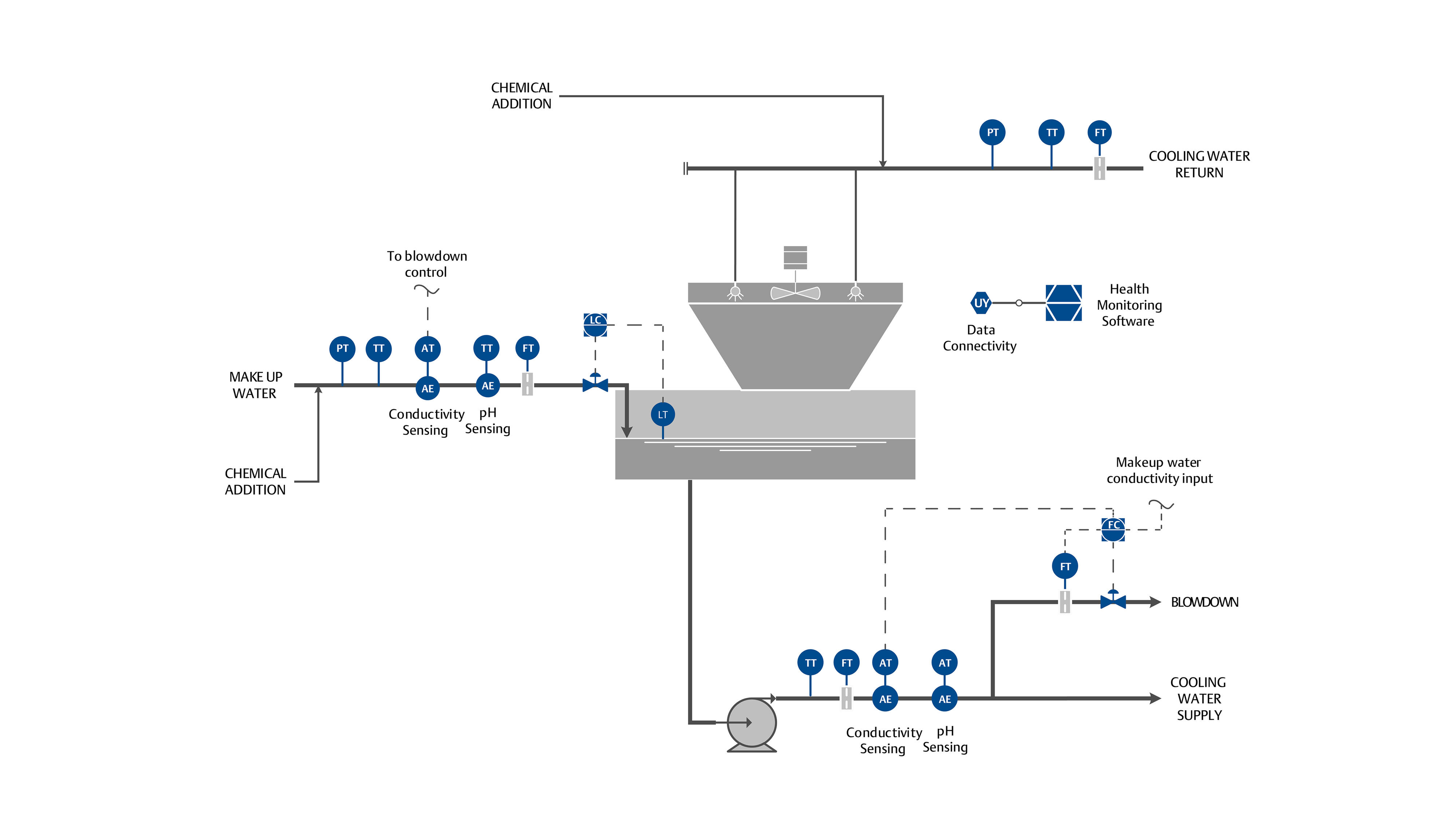

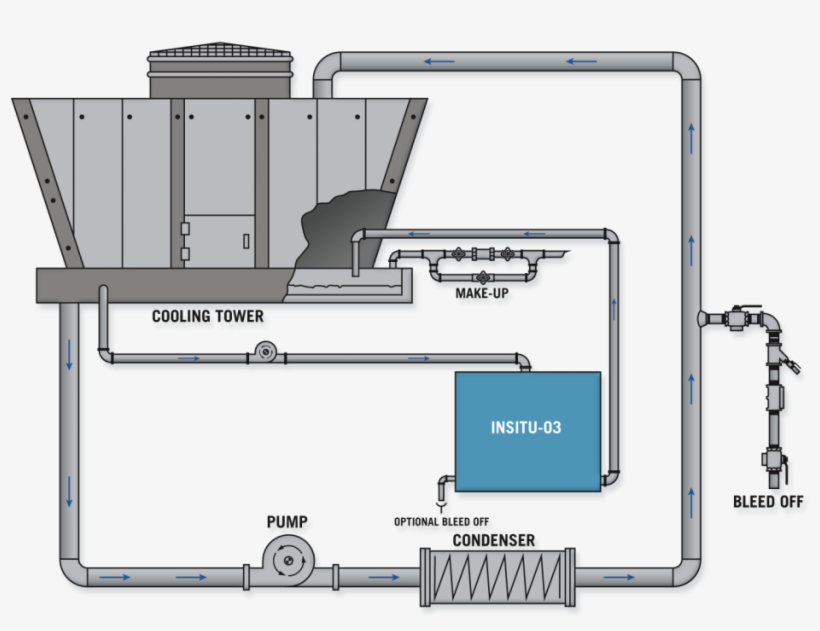

Makeup water refers to the water added to a cooling tower to compensate for water losses during the cooling process. These losses occur primarily through evaporation, drift (water droplets carried by the air), and blowdown (water discharged to maintain water quality).

Why is Makeup Water Essential?

The addition of makeup water serves several crucial purposes:

- Maintaining Water Level: Evaporation, drift, and blowdown constantly deplete the water volume in the cooling tower. Makeup water replenishes this volume, ensuring the tower operates at its optimal water level.

- Preventing System Failure: Insufficient water levels can lead to reduced cooling efficiency, potentially causing overheating of equipment and system failure.

- Maintaining Water Quality: Makeup water is typically treated to meet specific quality standards, contributing to overall water quality within the cooling tower. This helps prevent fouling, corrosion, and scaling, ensuring optimal heat transfer.

Factors Influencing Makeup Water Requirements

Several factors influence the amount of makeup water required for a cooling tower. These include:

- Climate: Higher temperatures and humidity lead to increased evaporation rates, necessitating a higher makeup water requirement.

- Cooling Tower Design: The design of the cooling tower, including its size and type, significantly impacts water loss rates and, consequently, makeup water needs.

- Operating Conditions: The operating conditions of the cooling tower, such as the temperature of the water entering and leaving the tower, affect the rate of evaporation.

- Water Quality: The quality of the makeup water influences the frequency of blowdown, which in turn affects makeup water requirements.

- Maintenance Practices: Proper maintenance, including regular cleaning and inspection, can minimize water losses and reduce makeup water needs.

Determining Makeup Water Requirements

Calculating the makeup water requirement involves considering the following:

- Evaporation Loss: This is the primary source of water loss and depends on the tower’s design, operating conditions, and climate.

- Drift Loss: Drift loss, typically a smaller percentage compared to evaporation, is influenced by the tower’s design and wind conditions.

- Blowdown Loss: Blowdown is a controlled water discharge used to maintain water quality and prevent the buildup of dissolved solids.

These factors are often analyzed using specialized software or engineering calculations to determine the precise makeup water requirement for a specific cooling tower.

Benefits of Optimized Makeup Water Management

- Reduced Water Consumption: Efficient makeup water management minimizes water consumption, contributing to sustainability and cost savings.

- Improved Cooling Efficiency: Maintaining optimal water levels enhances the cooling tower’s efficiency, leading to reduced energy consumption.

- Extended Equipment Lifespan: Properly managed makeup water contributes to a cleaner cooling system, reducing corrosion and scaling, and extending the lifespan of equipment.

- Reduced Environmental Impact: Minimizing water consumption and waste reduces the environmental impact of cooling tower operations.

FAQs Regarding Makeup Water Requirements

Q: What are the typical water quality standards for makeup water?

A: Water quality standards for makeup water vary depending on the specific cooling tower and its operating conditions. However, common requirements include low levels of dissolved solids, hardness, and alkalinity. Makeup water is often treated to meet these standards, ensuring optimal performance and minimizing corrosion and scaling.

Q: How often should I check the makeup water level in my cooling tower?

A: Monitoring the makeup water level is crucial for maintaining optimal performance. The frequency of monitoring depends on the specific cooling tower and its operating conditions. However, daily checks are generally recommended, with more frequent monitoring during periods of high demand or extreme weather.

Q: Can I use untreated water for makeup water?

A: Using untreated water for makeup water can lead to several issues, including fouling, corrosion, and scaling, which can significantly impact the cooling tower’s performance and lifespan. It is generally recommended to use treated water that meets the specific water quality standards for the tower.

Q: What are the potential consequences of using insufficient makeup water?

A: Insufficient makeup water can lead to several negative consequences, including:

- Reduced Cooling Efficiency: Low water levels affect the cooling tower’s ability to dissipate heat effectively, leading to potential overheating of equipment.

- System Failure: Insufficient water levels can cause the cooling tower to malfunction, leading to system failure and downtime.

- Increased Maintenance Costs: Fouling, corrosion, and scaling due to poor water quality can increase maintenance costs and shorten the lifespan of the cooling tower.

Q: How can I reduce my makeup water requirement?

A: Several strategies can be employed to reduce makeup water requirements:

- Optimize Tower Design: Choosing a cooling tower design that minimizes water losses through evaporation and drift can significantly reduce makeup water needs.

- Implement Water Conservation Measures: Implementing measures such as water-saving spray nozzles and efficient water distribution systems can reduce evaporation losses.

- Improve Water Quality: Treating makeup water to meet specific standards can reduce the need for frequent blowdown, leading to lower makeup water requirements.

- Regular Maintenance: Regular maintenance, including cleaning and inspection, can minimize water losses and reduce makeup water needs.

Tips for Effective Makeup Water Management

- Invest in Water Treatment: Properly treating makeup water to meet specific quality standards is crucial for long-term cooling tower performance and reduced maintenance costs.

- Regularly Monitor Water Quality: Monitor water quality parameters regularly to ensure compliance with established standards and identify any potential issues early.

- Implement Water Conservation Measures: Explore water conservation strategies, such as optimizing spray nozzles and reducing blowdown frequency, to minimize water consumption.

- Conduct Regular Inspections: Regularly inspect the cooling tower for leaks, corrosion, and other potential issues that can contribute to increased makeup water requirements.

Conclusion

Makeup water is a vital component of cooling tower operation, ensuring optimal performance and minimizing potential problems. Understanding the factors influencing makeup water requirements, implementing efficient management strategies, and adopting best practices for water conservation are essential for maximizing the efficiency and lifespan of cooling towers. By optimizing makeup water management, businesses can reduce operational costs, minimize environmental impact, and ensure the reliable operation of their cooling systems.

.png)

Closure

Thus, we hope this article has provided valuable insights into Understanding Makeup Water Requirements in Cooling Towers: A Comprehensive Guide. We appreciate your attention to our article. See you in our next article!