The Vital Role of Makeup Water in Cooling Tower Performance

Related Articles: The Vital Role of Makeup Water in Cooling Tower Performance

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Vital Role of Makeup Water in Cooling Tower Performance. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The Vital Role of Makeup Water in Cooling Tower Performance

- 2 Introduction

- 3 The Vital Role of Makeup Water in Cooling Tower Performance

- 3.1 Understanding Makeup Water: A Foundation for Efficient Cooling

- 3.2 Treatment Strategies for Optimal Makeup Water Quality

- 3.3 Monitoring Makeup Water Quality: A Continuous Process

- 3.4 FAQs on Makeup Water in Cooling Towers

- 3.5 Tips for Managing Makeup Water in Cooling Towers

- 3.6 Conclusion

- 4 Closure

The Vital Role of Makeup Water in Cooling Tower Performance

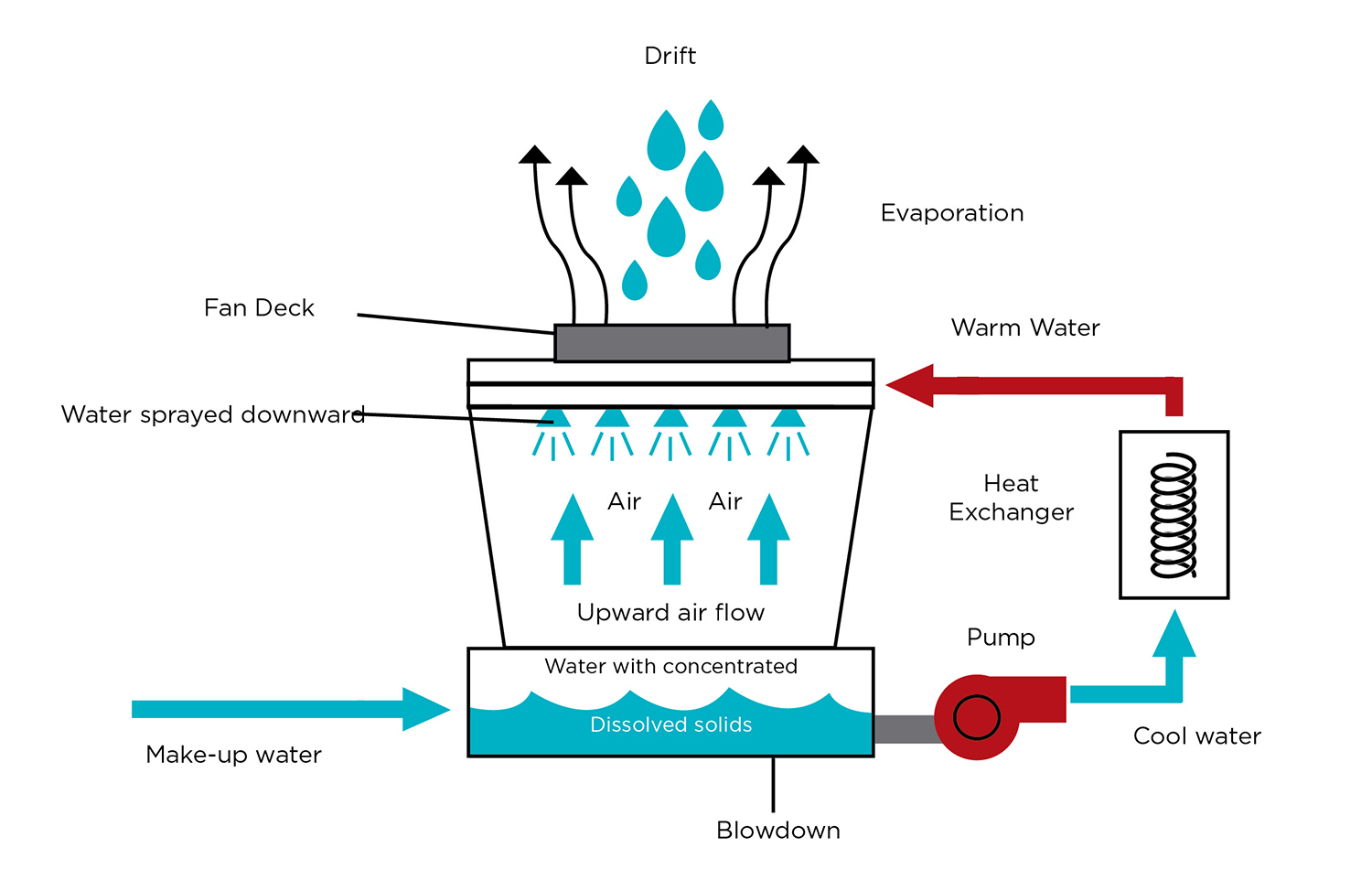

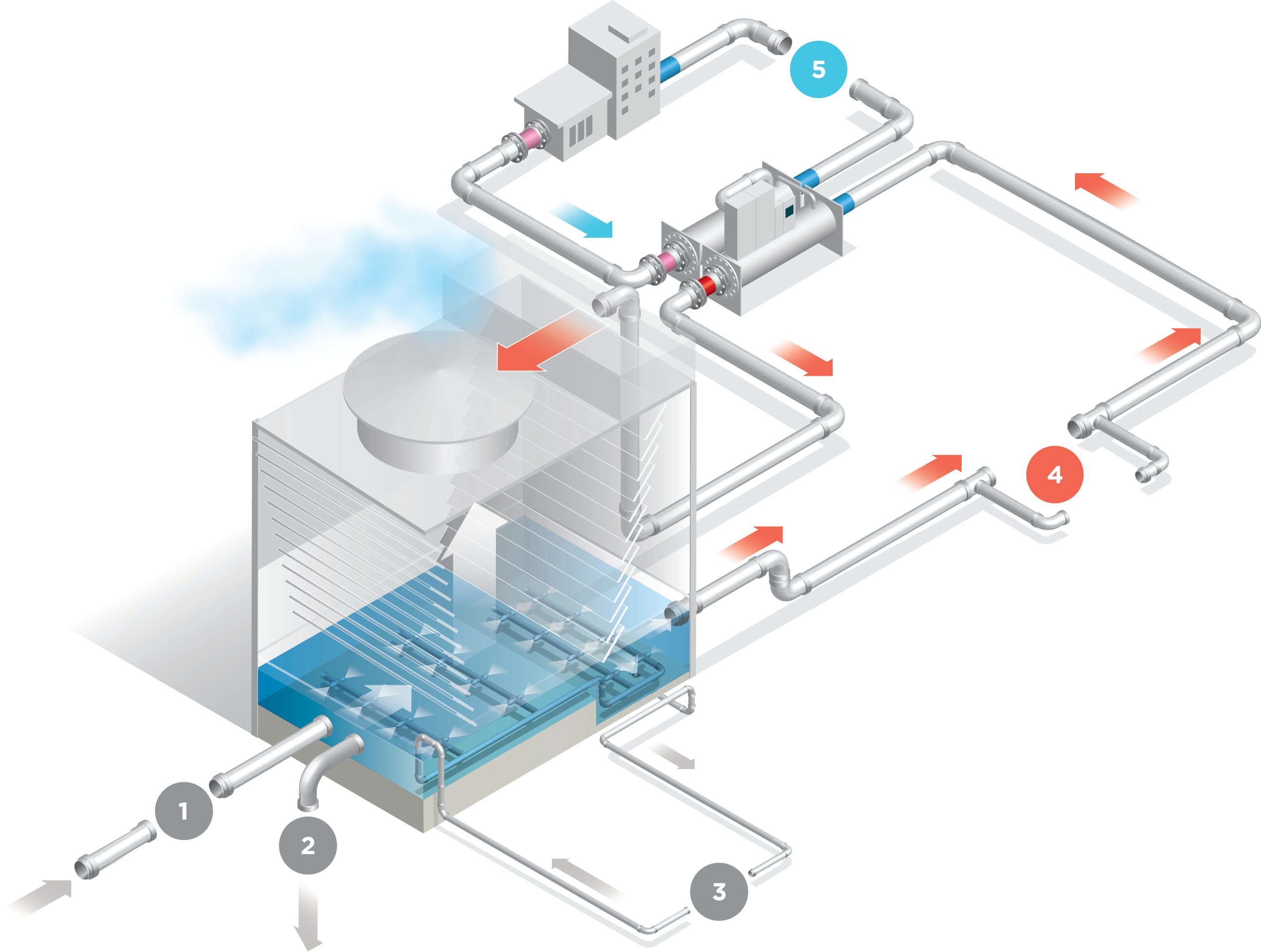

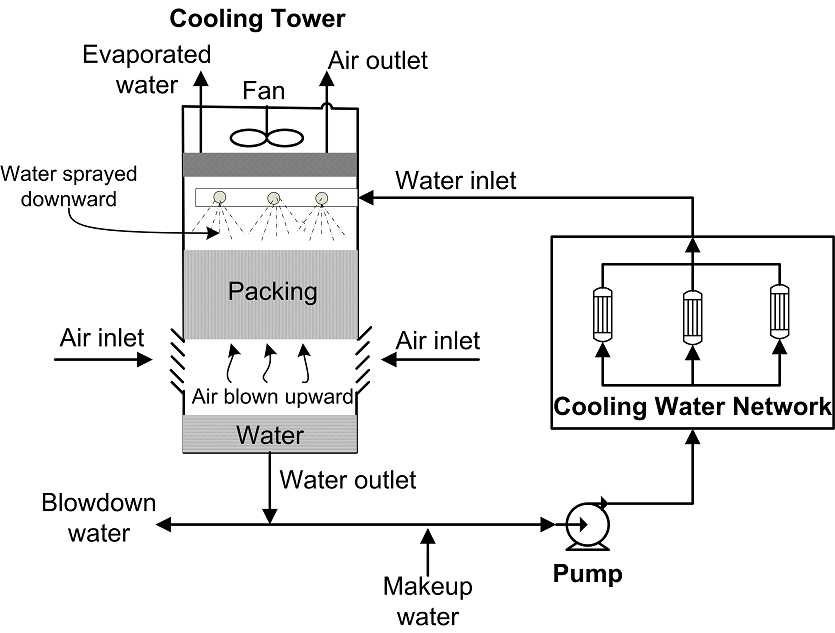

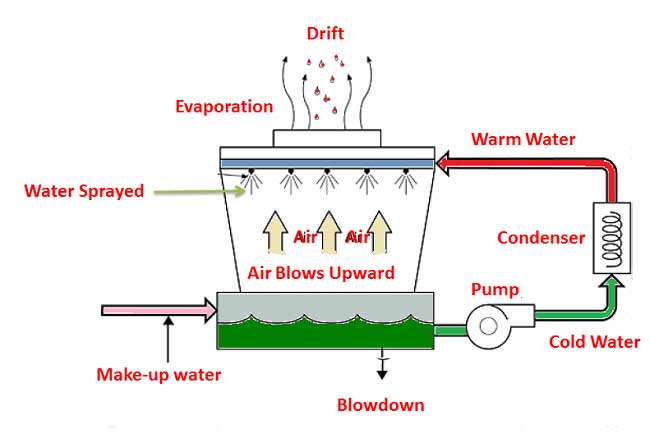

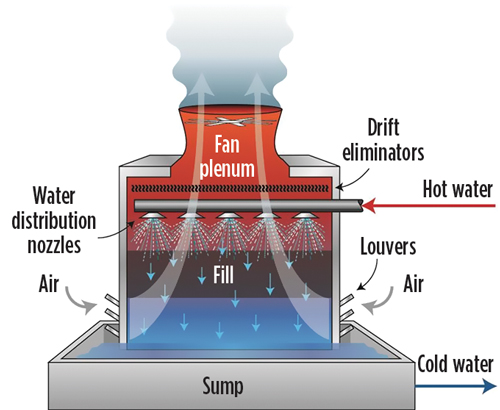

Cooling towers are essential components in various industrial processes, playing a crucial role in dissipating heat generated by machinery and equipment. Their efficient operation relies heavily on the quality and quantity of water circulating within the system. This is where the concept of "makeup water" comes into play, representing a critical aspect of cooling tower maintenance and performance.

Understanding Makeup Water: A Foundation for Efficient Cooling

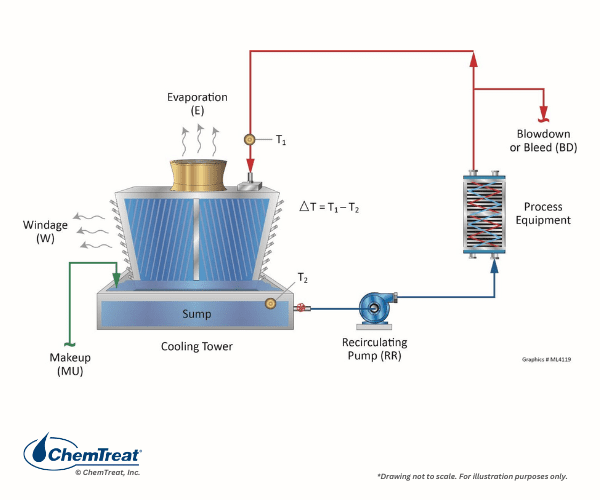

Makeup water refers to the fresh water added to a cooling tower system to compensate for water losses due to evaporation, blowdown, and leaks. These losses are unavoidable in a cooling tower’s operation, and replenishing the system with fresh water is essential to maintain optimal performance.

Evaporation: The primary loss mechanism in cooling towers is evaporation, where water turns into vapor as it absorbs heat from the circulating water. This process is crucial for the cooling function itself, but it necessitates replenishing the water lost.

Blowdown: Blowdown is a controlled process where a portion of the circulating water is discharged from the system to prevent the concentration of dissolved solids, such as calcium, magnesium, and other minerals. These solids can lead to scaling, corrosion, and reduced heat transfer efficiency.

Leaks: Leaks can occur at various points within the cooling tower system, from pipes and valves to seals and gaskets. These leaks result in water loss and require replenishment.

The Importance of Makeup Water Quality:

The quality of makeup water significantly impacts the performance, efficiency, and longevity of a cooling tower system. Impurities in the water can lead to:

- Scaling: Dissolved minerals in the makeup water can precipitate out and form deposits on heat transfer surfaces, reducing the cooling efficiency and potentially leading to corrosion.

- Corrosion: Certain chemicals and impurities in the makeup water can accelerate corrosion of the cooling tower components, leading to premature failure and costly repairs.

- Biological Growth: Makeup water containing organic matter can promote the growth of bacteria, algae, and other microorganisms within the cooling tower, leading to fouling and clogging of the system.

- Chemical Reactions: Impurities in the makeup water can react with other chemicals in the cooling tower system, forming undesirable byproducts that can damage components or affect cooling performance.

Treatment Strategies for Optimal Makeup Water Quality

To ensure the longevity and efficient operation of a cooling tower, it is crucial to treat makeup water effectively. The specific treatment methods employed depend on the nature and concentration of impurities in the raw water source. Common treatment techniques include:

1. Filtration: Physical filtration removes suspended solids, such as sand, dirt, and debris, from the makeup water. Various filtration methods, including sand filtration, cartridge filtration, and membrane filtration, can be used depending on the size and nature of the particles to be removed.

2. Softening: Water softening removes calcium and magnesium ions, which are responsible for hardness. Softening processes like ion exchange or lime softening are employed to prevent scale formation and corrosion.

3. Chemical Dosing: Adding chemicals to the makeup water can neutralize corrosive substances, control biological growth, and prevent scale formation. Common chemicals used for this purpose include:

- Corrosion inhibitors: These chemicals form protective layers on metal surfaces, preventing corrosion.

- Biocides: Biocides kill or inhibit the growth of bacteria, algae, and other microorganisms in the cooling tower.

- Scale inhibitors: These chemicals prevent the formation of scale by altering the crystal structure of the minerals in the water.

4. Reverse Osmosis: Reverse osmosis is a membrane filtration process that removes a wide range of impurities, including dissolved salts, organic matter, and bacteria. This technology is particularly effective for producing high-purity makeup water.

5. Disinfection: Disinfection is essential to eliminate harmful bacteria and other microorganisms from the makeup water. Common disinfection methods include:

- Chlorination: Adding chlorine to the water kills bacteria and other microorganisms.

- Ultraviolet (UV) disinfection: UV light inactivates microorganisms by damaging their DNA.

6. Dechlorination: If the makeup water source contains high levels of chlorine, dechlorination is necessary to remove the chlorine before it enters the cooling tower. Dechlorination can be achieved using activated carbon filters or chemical reducing agents.

7. pH Adjustment: The pH of the makeup water must be within a specific range to minimize corrosion and scale formation. pH adjustment can be achieved by adding acids or bases to the water.

8. Dissolved Oxygen Removal: Dissolved oxygen in the makeup water can contribute to corrosion. Oxygen removal can be achieved using degassing techniques or chemical reducing agents.

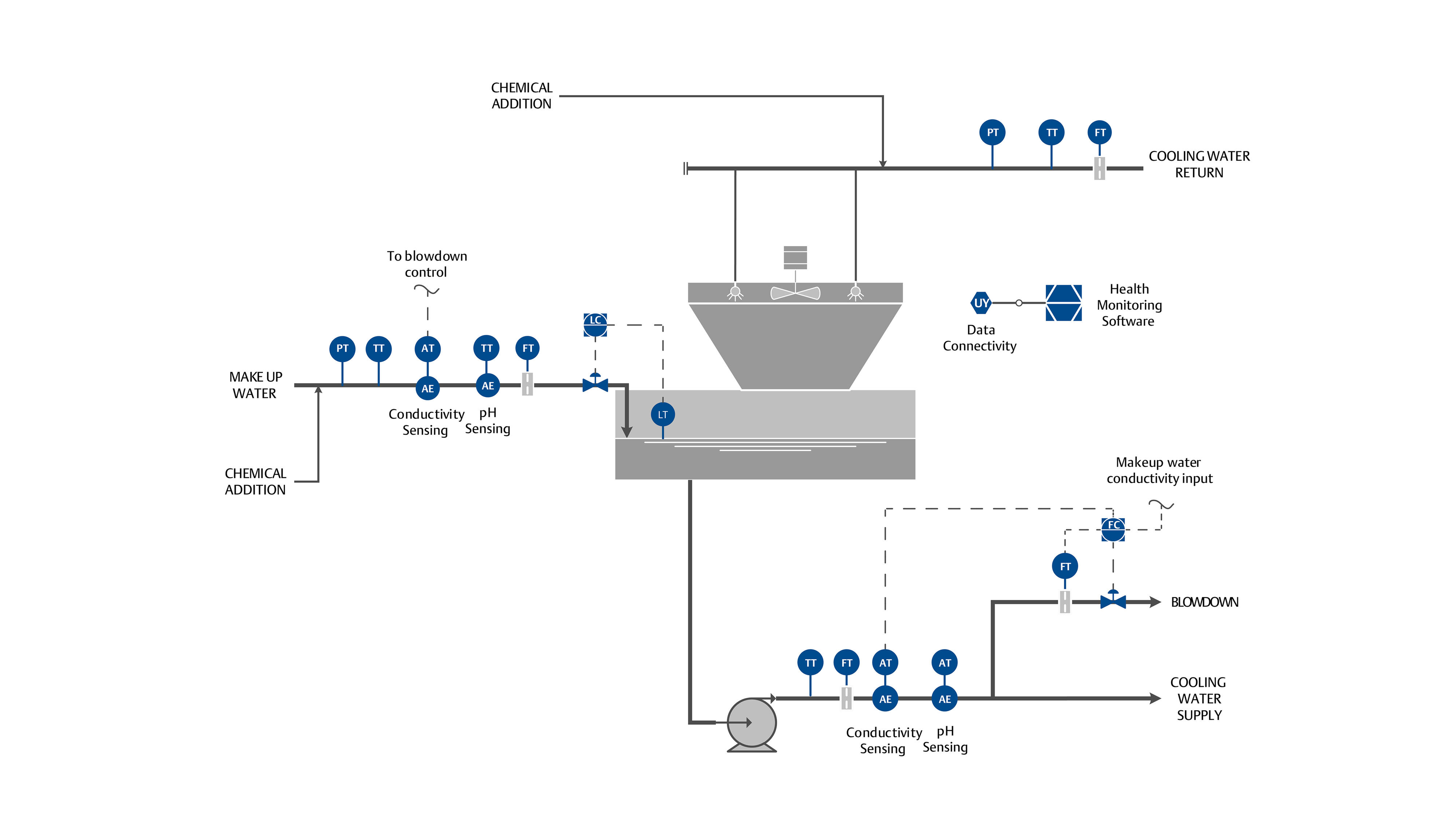

Monitoring Makeup Water Quality: A Continuous Process

Regular monitoring of the makeup water quality is crucial to ensure optimal cooling tower performance. Monitoring parameters include:

- pH: Monitoring pH helps ensure the water is within the desired range to minimize corrosion and scale formation.

- Conductivity: Conductivity measures the dissolved solids in the water, providing an indication of the potential for scale formation.

- Hardness: Measuring hardness helps determine the effectiveness of water softening treatments.

- Dissolved oxygen: Monitoring dissolved oxygen levels helps assess the risk of corrosion.

- Microbial contamination: Regular testing for microbial contamination helps identify and control the growth of bacteria, algae, and other microorganisms.

FAQs on Makeup Water in Cooling Towers

1. What is the ideal makeup water quality for a cooling tower?

The ideal makeup water quality depends on the specific cooling tower system and its operating conditions. However, in general, makeup water should be free from suspended solids, have low hardness, minimal dissolved oxygen, and be free from microbial contamination. The specific water quality requirements are often outlined in the cooling tower manufacturer’s recommendations and local regulations.

2. How often should I add makeup water to my cooling tower?

The frequency of makeup water addition depends on the evaporation rate, blowdown rate, and leak rate of the cooling tower. Generally, makeup water should be added regularly to maintain the water level within the operating range.

3. What are the consequences of using poor quality makeup water?

Using poor quality makeup water can lead to a range of problems, including scaling, corrosion, biological growth, and reduced cooling efficiency. These issues can result in increased maintenance costs, reduced equipment lifespan, and potential environmental damage.

4. How can I determine the best treatment method for my makeup water?

The best treatment method for makeup water depends on the specific impurities present in the raw water source. A water analysis should be conducted to identify the contaminants and their concentrations. Based on this analysis, a suitable treatment plan can be developed.

5. What are the benefits of using treated makeup water?

Using treated makeup water offers several benefits, including:

- Improved cooling efficiency: Reduced scaling and fouling on heat transfer surfaces enhance cooling efficiency.

- Extended equipment lifespan: Corrosion protection and reduced biological growth extend the lifespan of cooling tower components.

- Reduced maintenance costs: Minimizing scaling, corrosion, and biological growth reduces maintenance requirements and associated costs.

- Improved environmental performance: Reduced water consumption, minimized chemical usage, and reduced waste generation contribute to a more sustainable operation.

Tips for Managing Makeup Water in Cooling Towers

1. Regular Monitoring: Monitor the makeup water quality regularly to ensure it remains within the desired range.

2. Proper Treatment: Implement appropriate treatment methods to remove impurities and control microbial growth.

3. Optimize Blowdown: Adjust the blowdown rate to maintain a balance between minimizing dissolved solids and minimizing water loss.

4. Minimize Leaks: Regularly inspect and maintain the cooling tower system to identify and repair any leaks promptly.

5. Implement a Water Management Plan: Develop a comprehensive water management plan that addresses makeup water quality, treatment, monitoring, and disposal.

Conclusion

Makeup water plays a critical role in maintaining the efficient operation and longevity of cooling towers. Ensuring its quality through appropriate treatment methods is essential for preventing scaling, corrosion, and biological growth, which can negatively impact cooling performance and increase maintenance costs. By implementing effective water management practices, including regular monitoring, proper treatment, and minimizing leaks, industries can optimize their cooling tower systems, enhance efficiency, and promote sustainability.

Closure

Thus, we hope this article has provided valuable insights into The Vital Role of Makeup Water in Cooling Tower Performance. We thank you for taking the time to read this article. See you in our next article!