The Crucial Role of Makeup Water Valves in Water Systems

Related Articles: The Crucial Role of Makeup Water Valves in Water Systems

Introduction

With great pleasure, we will explore the intriguing topic related to The Crucial Role of Makeup Water Valves in Water Systems. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of Makeup Water Valves in Water Systems

In the intricate network of pipes and valves that constitute a water system, the makeup water valve plays a pivotal role. This unassuming component, often overlooked amidst the complexity of plumbing infrastructure, serves as a critical guardian of water quality, pressure, and system integrity. Understanding its function and significance is essential for maintaining a reliable and efficient water supply.

Delving into the Function of Makeup Water Valves

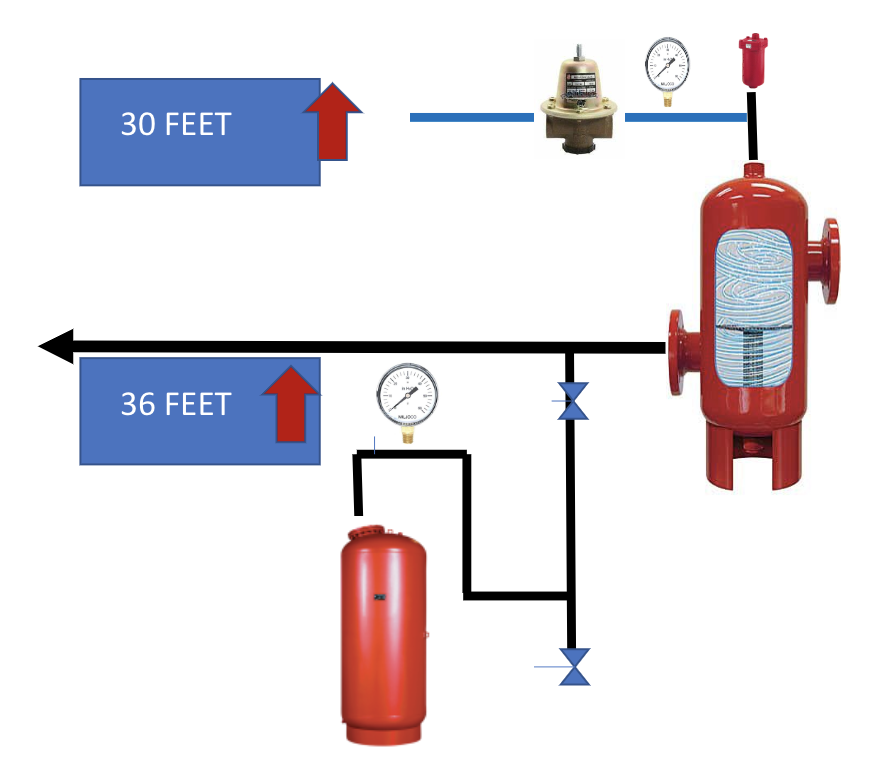

Makeup water valves, also known as automatic makeup valves or feed water valves, are designed to maintain a constant water level within a closed-loop water system. These systems, commonly found in boilers, cooling towers, and other industrial applications, rely on a continuous supply of water to compensate for losses due to evaporation, leakage, or consumption.

The valve operates on a simple yet ingenious principle: it automatically replenishes the water level when it drops below a predetermined threshold. This process is achieved through a pressure-sensitive mechanism that senses the water level within the system. When the level falls, the mechanism triggers the valve to open, allowing fresh water to enter the system and restore the desired level.

Types of Makeup Water Valves

Makeup water valves are available in various types, each designed to cater to specific needs and system configurations. Common types include:

- Float-operated valves: These valves employ a float mechanism that rises and falls with the water level. When the level drops, the float descends, activating the valve to open and replenish the water supply.

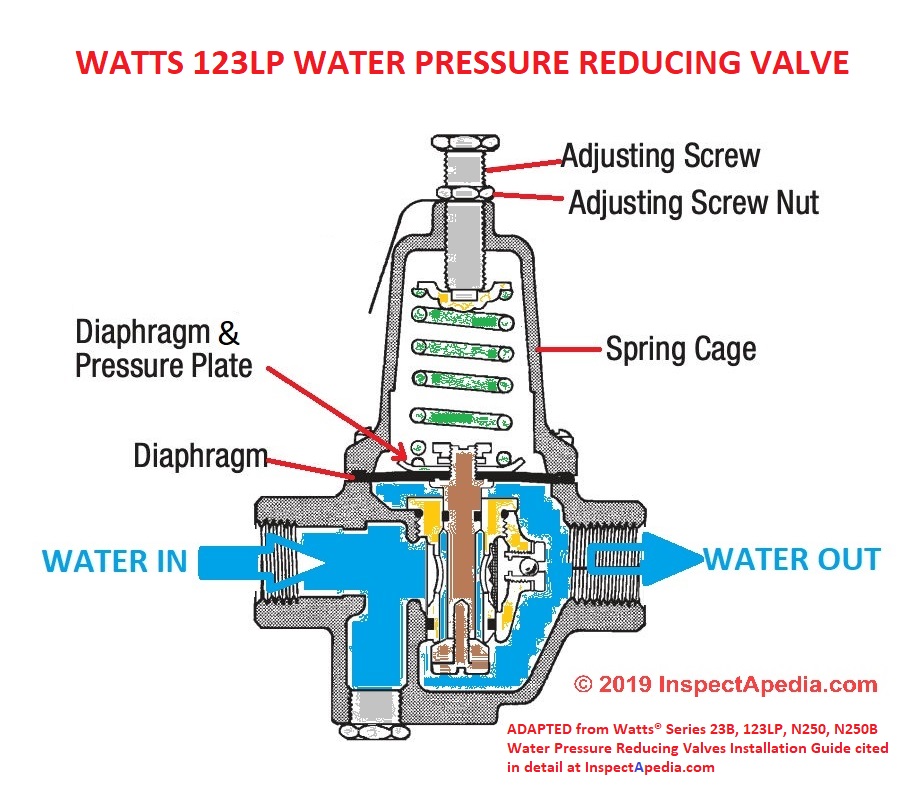

- Pressure-operated valves: These valves utilize a pressure-sensitive mechanism that responds to changes in system pressure. When the pressure drops due to a decrease in water level, the mechanism opens the valve to replenish the water.

- Electronic valves: These valves incorporate electronic sensors to monitor water level and pressure. The sensors send signals to a control unit that regulates the valve’s operation, ensuring precise water level maintenance.

The Importance of Makeup Water Valves in Water Systems

The makeup water valve’s contribution to a water system’s efficiency and reliability is multifaceted:

- Maintaining Water Level: The valve’s primary function is to ensure a constant water level within the system. This is crucial for preventing system malfunction and ensuring optimal performance. In boilers, for instance, a consistent water level is essential for efficient heat transfer and preventing overheating. In cooling towers, maintaining a proper water level is vital for effective heat dissipation and preventing corrosion.

- Protecting Against System Damage: By preventing water level fluctuations, the valve protects the system from damage caused by low water levels. This is particularly important in boilers, where low water levels can lead to overheating and potential explosions.

- Ensuring Water Quality: The valve plays a vital role in maintaining water quality by preventing contamination. By replenishing the water supply with fresh water, the valve helps to dilute any impurities that may accumulate over time.

- Reducing Energy Consumption: By maintaining a constant water level, the valve helps to reduce energy consumption. In boilers, for example, maintaining a consistent water level ensures efficient heat transfer, minimizing energy waste.

Benefits of Using Makeup Water Valves

Implementing makeup water valves in water systems offers numerous benefits:

- Improved System Efficiency: By ensuring a consistent water level, the valve optimizes system performance, reducing downtime and maintenance costs.

- Enhanced Safety: The valve’s ability to prevent low water levels mitigates the risk of system damage and potential hazards, enhancing overall safety.

- Extended System Lifespan: By protecting the system from the detrimental effects of water level fluctuations, the valve contributes to a longer lifespan for the system components.

- Reduced Maintenance Costs: By preventing system malfunctions and reducing the need for repairs, the valve helps to minimize maintenance expenses over time.

Factors to Consider When Selecting a Makeup Water Valve

Choosing the right makeup water valve for a specific application requires careful consideration of several factors:

- System Requirements: The valve’s capacity, pressure rating, and flow rate should be compatible with the system’s needs.

- Water Quality: The valve’s material and design should be suitable for the type of water being used.

- Environmental Conditions: The valve’s operating temperature and humidity tolerance should be compatible with the environment in which it will be installed.

- Maintenance Requirements: The valve’s ease of maintenance and repair should be considered.

FAQs about Makeup Water Valves

Q: What is the difference between a makeup water valve and a pressure relief valve?

A: While both valves play important roles in water systems, they serve distinct functions. A makeup water valve replenishes the water level, while a pressure relief valve releases excess pressure to prevent system damage.

Q: How often should I check my makeup water valve?

A: Regular inspection and maintenance are crucial for ensuring the valve’s proper functioning. The frequency of inspection depends on the valve’s type and the specific system requirements. Consult the manufacturer’s recommendations for guidance.

Q: What are the signs that my makeup water valve is malfunctioning?

A: Signs of malfunction include:

- Fluctuating water level: The valve may not be effectively replenishing the water level.

- Frequent valve activation: The valve may be opening and closing more often than usual, indicating a possible leak or other issue.

- Unusual noises: The valve may emit unusual noises during operation, indicating a potential malfunction.

Q: Can I replace my makeup water valve myself?

A: Replacing a makeup water valve can be a complex task. It is recommended to consult a qualified plumber or technician to ensure proper installation and avoid potential damage to the system.

Tips for Maintaining Makeup Water Valves

- Regular Inspection: Inspect the valve regularly for signs of damage, corrosion, or leaks.

- Cleaning: Clean the valve periodically to remove debris and prevent clogging.

- Testing: Test the valve’s operation periodically to ensure it is functioning properly.

- Lubrication: Lubricate the valve’s moving parts as needed to prevent wear and tear.

Conclusion

The makeup water valve, though often overlooked, is an indispensable component of water systems. Its ability to maintain a consistent water level, protect against system damage, and ensure water quality makes it a vital contributor to system efficiency, reliability, and safety. By understanding its function and importance, and by implementing proper maintenance practices, you can ensure the long-term performance and integrity of your water system.

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of Makeup Water Valves in Water Systems. We hope you find this article informative and beneficial. See you in our next article!